CobaDGS - Zero Emission Solution

CobaDGS - Zero Emission Solution

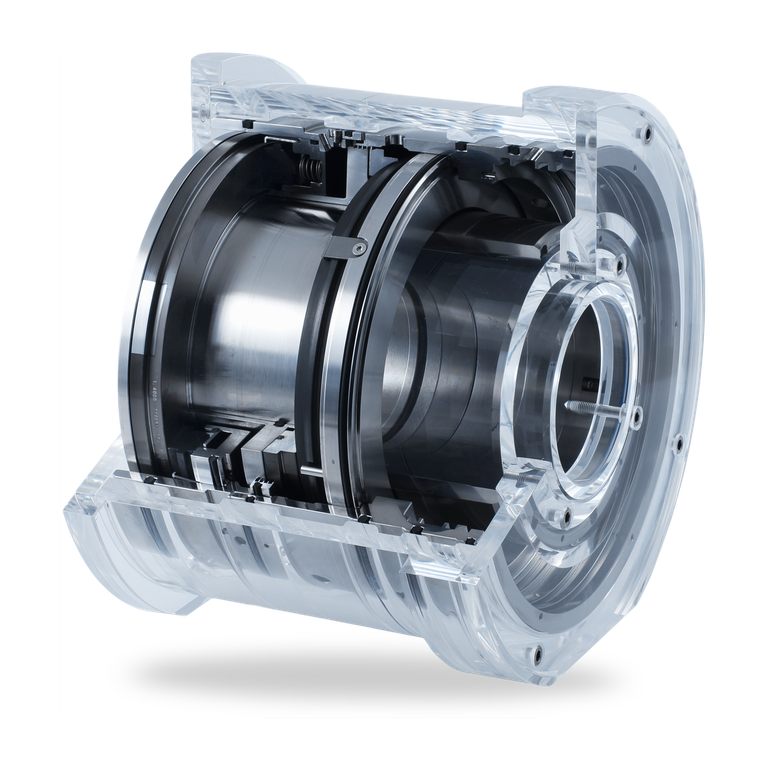

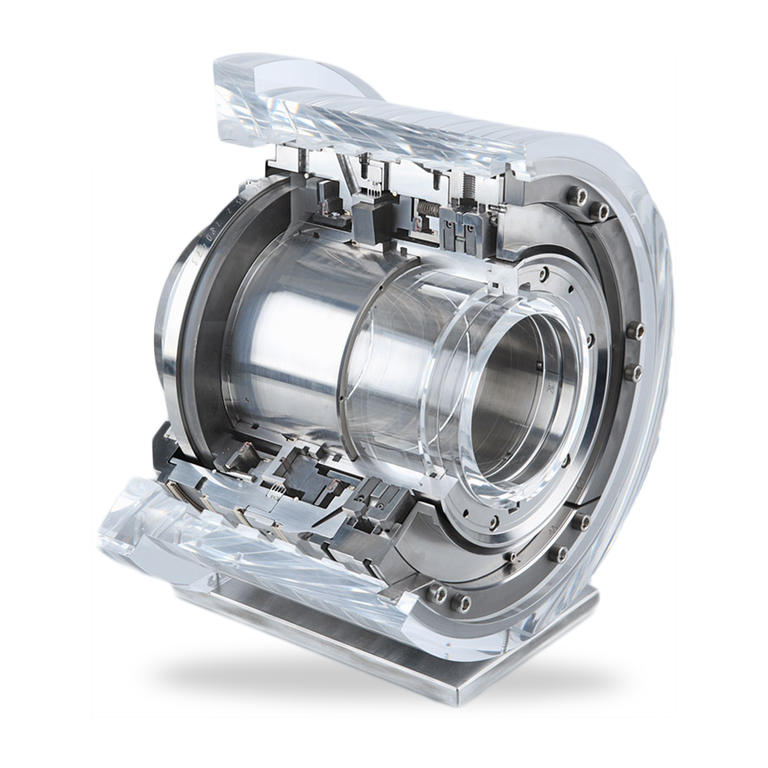

CobaDGS drawing

E* Buffer gas supply - optional

A Seal gas supply

B Primary vent

C Secondary seal gas supply

S Secondary vent

D Separation gas supply

| Item | Description |

| 1 | (Seat) Rotating seal face |

| 2 | (Seal face) Stationary seal face |

| 3 | Thrust ring |

| 4 | Spring |

| 5 | Shaft sleeve |

| 6 | Housing |

| 7 | Labyrinth |

| 8 | DGS as secondary seal |

| 9 | CobaSeal as separation seal |

| 10 | Intermediate labyrinth |

CobaDGS - Zero Emission Solution

Features

The sealing solution for reduction of methane-/ process gas emissions

- Gas-lubricated

- Bi-directional

- Ready-to-fit cartridge unit

- Available for following seal arrangements: single and tandem

- Co-axial primary seal

- Separation seals as CobaSeal, carbon rings or labyrinths optional

Advantages

- No methane-/ process gas emissions

- Supplied with clean nitrogen (no dew point and dirt problems)

- Robust

- Offers higher safety than a double seal

- Upgrade-possibility of existing single, double and tandem seals

- No modification of the compressor necessary

- Efficient alternative to hermetically sealed systems

- For compressors with gas- and steam turbines, as well as with electric drive

Materials

Stationary seal face: Silicon carbide with DLC-coating, DiamondFace-coating optional

Rotating seal face (Seat): Silicon carbide with DLC-coating, DiamondFace-coating optional

Secondary seals: FKM or other elastomers, depending on product gas composition

Metal parts: 1.4006 or other stainless steels

Other materials on request.

Dimensions on request.

Rotating seal face (Seat): Silicon carbide with DLC-coating, DiamondFace-coating optional

Secondary seals: FKM or other elastomers, depending on product gas composition

Metal parts: 1.4006 or other stainless steels

Other materials on request.

Dimensions on request.

Standards and approvals

- NACE

- Compliant to TA Luft (German Clean Air Act) (tandem seal)

Recommended applications

- Pipelines

- Gas storages

- Oil and gas industry

- Chemical industry

- Power plants

- Centrifugal compressors

- Turbo expander

- Turbines

- Pumps

- Blower

- LNG

- CCUS

- Hydrogen

- Alternative fuels production

- Power generation

Product variants

Optionally available

High pressure nitrogen generator

On-site generation of nitrogen.

Ensures continuous, uninterrupted nitrogen supply

Solves the logistics problem, especially for sites in remote, hard-to-reach areas.

No more hassle transporting the nitrogen.

Nitrogen generation is based on pressure swing adsorption. Storage at 330 bar – for intermittent generation/compression and back-up supply – then reduction to the required pressure.

The complete nitrogen production and supply system comes in a container which should be installed out of ATEX area.

Required power supply: Heavy current, 400V, 50Hz/60Hz, 3 Ph

Similar products

DGS

- Gas-lubricated

- Uni-directional or bi-directional

- Ready-to-fit cartridge unit

- Single, double, tandem and tandem with intermediate labyrinth available

- Separation seals as labyrinths, carbon rings or CobaSeal are optionally available

MDGS

- Gas-lubricated

- Bi-directional

- Compact, radial design

- Ready-to-fit cartridge unit, also available as a component seal

- Single, double, tandem seal and tandem with intermediate labyrinth available

PDGS

- Gas-lubricated

- Uni-directional or bi-directional

- Elastomer-free

- Ready-to-fit cartridge unit

- Single, double, tandem seal and tandem with intermediate labyrinth available

- Separation seals as labyrinths, carbon rings or CobaSeal are optionally available